Masters of Wood

Hannes and Kurt Prader grew up around wood. Their master carpentry business in South Tyrol is where traditional craftsmanship meets the most modern technology. And

because the family company makes no compromises on quality, it has relied on sliding solutions from Hawa Sliding Solutions right from the beginning.

Barbian, population 1710 , 453 to 2,259 m ASL, is situated in the heart of Europe, says Hannes Prader while looking out his office window. The Trostburg mountain rises in front of the mountain face on the opposite side of the valley, where the A22 Brenner motorway leads through. Huge trucks travel between Modena in the south and the Brenner Pass to mthe north. At the same time, the Prader master carpentry shop is completely surrounded by its main resource: fragrant forests rise from the base of the valley to the tree line.

Order by mouse-click

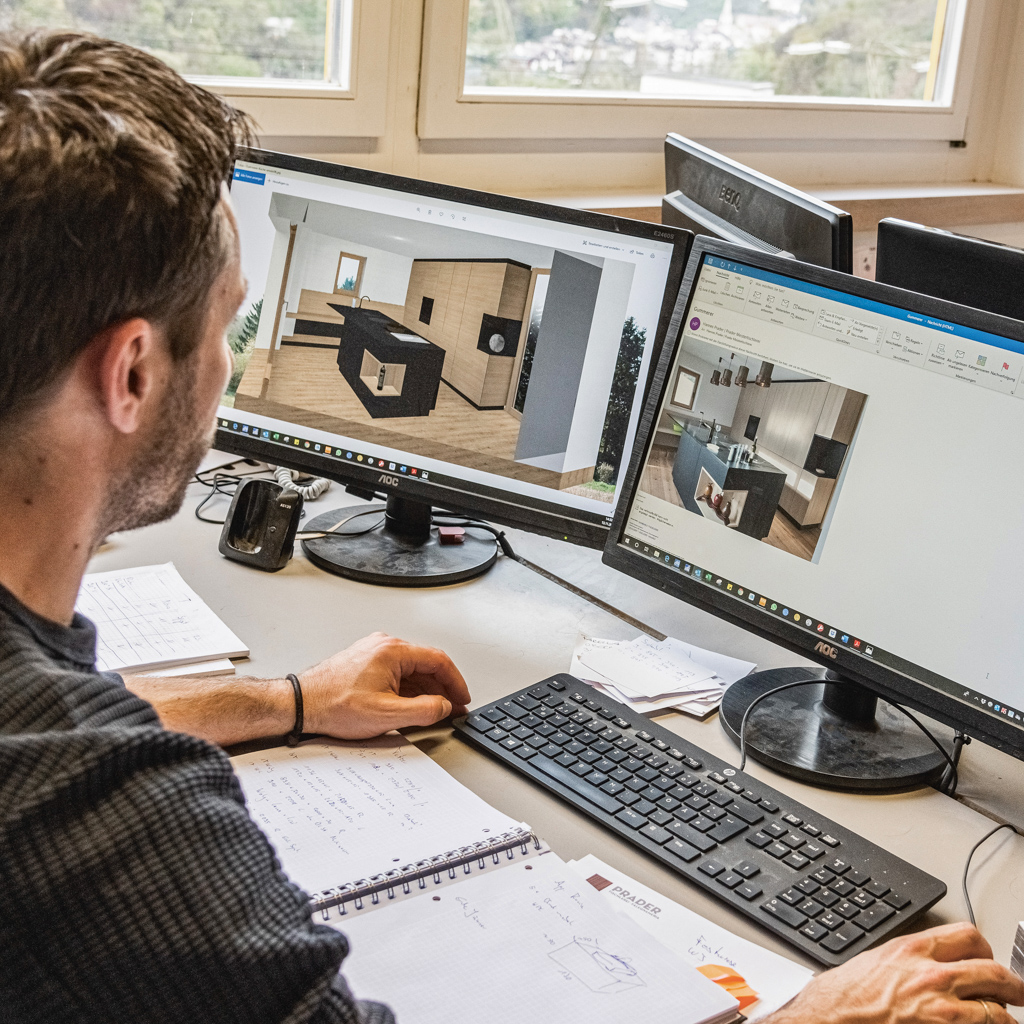

While Kurt Prader (35) prefers the fieldwork of mounting and installation, Hannes Prader (41) is happiest working at the office. That’s where all streams come together. The master carpenter likes his tidied up work table. “The table consists of oak wood with a linoleum covering over it,” says Hannes Prader. His current projects are imposing: outfitting a complete apartment from kitchen to bathroom in Brixen, a hotel project in Wolkenstein-Gröden, a residential complex with seven residential units in Villanders. Working at his screen, Hannes Prader designs the made-to-measure furniture and specialized doors. A 3D CAD program generates the blueprints. At the push of a button, he can forward all the data to the adjacent workshop – and place orders for sliding solutions from Hawa Sliding Solutions.

Industry 4.0 in Barbian

State-of-the art machines stand ready at the master carpentry shop. The complement includes a 5-axis CNC lathe and fully automated panel saw. “Industry 4.0 in Barbian!” comments Prader proudly. Stalwart hand tools are always ready and at hand as well: variations of planes, milling machines, drills, ferrules and hammers. 14 master carpenters, journeymen and apprentices make everything imaginable to measure. This includes kitchens, sideboards, libraries, bar stools, bedrooms, beds and wall cladding made of wood. However naturally also front and interior doors, including soundproofed and fire protection doors in a wide range of individual versions. “We are members of the KOBRA regional consortium for fire protection doors, which makes us a sales partner of HAWA Suono,” says Prader. Whether it's architectural hardware or furniture fittings: many designs also integrate folding, pivoting and stackable sliding solutions.

We proceed like you would with Lego Technic: we stick exactly to the installation instructions.

Growing up with the HAWA Junior

Hannes Prader has been familiar with Hawa Sliding Solutions mright from the beginning. In fact, he grew up with HAWA Junior. At that time, this meant a traditional interior sliding door made of oak with a track on the wall. Today he recommends the HAWA Concepta and HAWA Folding Concepta pivot and folding/ slide-in fittings systems for kitchens. And naturally, he's still recommending all versions of the HAWA Junior line as well. The systems are compatible with every idea. “There is little to nothing in the way of comparable solutions,” says Prader enthusiastically. When all the delivered individual parts fit together perfectly, the system's movement will function “forever”. The best thing about his profession? “Making buildings into living spaces! When we go into a building under construction, we find concrete, bricks and utility lines. When we leave, you can cook, sleep and live inside,” says Prader. His master craftsman diploma dated October 12, 2011 hangs on the wall, next to a “Design and Carpentry Craftsmanship Award” from 2013. These are joined by artworks by his three children and below, a drawing on wood with the caption: “Prader special doors”.

The father, Konrad, founded the company in 1973. His son Hannes later attended a technical school for carpentry. He then obtained his apprentice craftsman diploma and later, his master craftsman diploma. He began working at the company in 1990. “Back then we drew everything by hand and made 1:1 models in the workshop”, he remembers. Then in 2006, his brother Kurt joined too. The company's infrastructure was optimized with the addition of a 5-axis CNC machining center. Planning was transitioned to 3D CAD systems four years ago, which are connected to the machine park. To raise the profile for joiners/ cabinet makers, Hannes Prader works on behalf of the South Tyrol Association of Master Craftspersons. He’s convinced that “wood will remain the material of the future” and believes care should be taken to preserve this renewable resource. He’s pleased that more and more of his contemporaries are coming to share his view. In any event, demand for wood products is only growing.

Kitchen enthusiast

For Hannes Prader, the most interesting furniture is found in the kitchen. Life's workshop, as it were. Power, water, fire, cabinets, storage, sliding solutions: everything here has to function. When a kitchen hasn’t been planned properly, one feels uncomfortable using it. Not all kitchens can or have to be realized in such grand style as the prototypes at Eurocucina, one of the world’s leading trade fairs for kitchens held in Milan, Italy. The ultimate furniture islands and walls that unfold like magic within kitchen workshops are just as stunning and effective at a smaller scale.

A preference for walnut

Although his kitchen tends to be small, compact and traditional, he does have a pantry, says Hannes Prader. From all available options, he chose wood coated in dark red paint for the lower cabinets and visible walnut for the upper cabinets. Although he lives, works, hikes and mountain bikes among Swiss pine, he prefers the aesthetics of walnut. The grain makes the fine wood come to life. Currently oak is also in high demand. The structure, color and durability of this trendy wood make it a favourite. When furniture should be unpretentious, modern and yet have a pleasant odor, there’s the perfect Swiss pine compromise: outside coated, inside left natural. This means you enter a fragrant inner world whenever you open it up.

3 tips from the Master Carpenter

“The better the preparations for mounting a sliding solution from Hawa Sliding Solutions, the smoother the mounting goes”, says Hannes Prader.

1. Planning

Take extra care to verify all dimensions during the planning stage. If questions arise, contact a specialist at Hawa Sliding Solutions – someone is usually standing by to help you immediately.

2. Care

Take special care when opening the delivered package and components.

3. Information

Even if the operating instructions are extremely long due to all the languages: follow each mounting step exactly. In Lego Technic too, you simply cannot leave anything out.